Making Shims for Dynafit Bindings and Bellowed Boots

Dynafit bindings and Scarpa F1 or F3 bellowed boots are a match made in heaven, yet officially you are not suppose to use them together. Perish the thought! The reasoning is that Dynafits rely on a fixed boot sole-length to work properly, and because the F1 & F3’s flex, the effective sole length changes, which in the worst case can disengage the heel prongs from the boot and send you for a faceplant. Because of this, people have been placing shims on their skis to essentially keep the boot from over-flexing when it is in ski mode. Scarpa makes shims for this, but they tend to be about 650% overkill. All you really need is a tiny little puck.

I’ve been making my own pucks for a while and have experimented with different designs before settling on the one shown below. The pucks have to be screwed on to the ski – epoxy is not enough. I got tired of moving pucks from ski to ski (especially as my wife is the Emelda Marcos of Dynafit bindings), so once a year or so I’ll run off a batch of these shims and then use them or hand them out as Halloween treats.

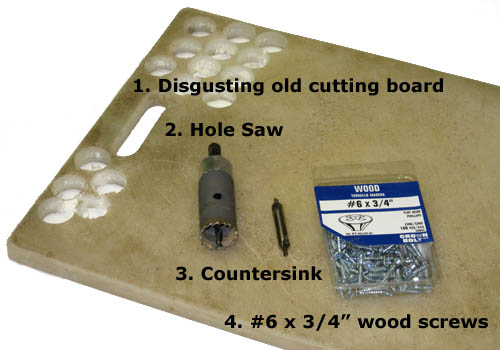

The Tools of the Shim Trade:

The cutting board is roughly 3/4″ thick. I use a 1″ hole saw, but anything close will do. The counter sink is a nice option, but you can also do the same thing with a drill bit. The screws are just basic wood screws.

Using the hole saw in a drill press or hand drill, drill through the cutting board. Hole saws are made for cutting holes, but in this case, you are keeping the scrap, so they are more like “puck saws.” The nice thing about using a hole/puck saw is that it creates a center-hole at the same time.

Next, use a countersink bit, or a drill bit slightly larger than the screw head and countersink the hole. Since the cutting board material and screws are the same length, the depth of your countersink will be the depth that the screw penetrates the ski, so go down about 1/4″ of an inch. Not too much… but not too little.

Make a bunch of them while you are at it.

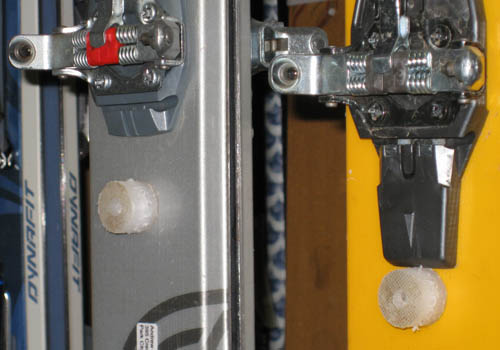

Next, place the boot in the binding and move the puck around until it is under a sole lug. Mark it with a pen, or just remember the location, then drill into the ski with a 7/64″ bit. Be careful when tightening the screws, as they can snap off, which is a bummer as you have to drill again right next to a blown hole.

Viola! Mount’em up and go skiing.

The pucks will interfere with ski crampons, but crampons are worthless anyway (a future topic), so it is a small price to pay.

________________________________

Help support StraightChuter.com and get 15% off on the green speed machine Scarpa F1 Boots from Backcountry.com! Click the photo below…

Category: 02 Gear

Outstanding. I have been using the 100 pound a piece Scarpa made shims that fit in the crampon slots….I like this much better. Thanks!

Glad to hear it. I’ve also seen the little Dynafit heel lifter spacers used as shims, but I like them better when used for their original purpose. The downside of this type of design is that you have to put another hole in your ski, but it is a small one.

for the lazy types, if you have a sailing shop nearby, you will find similar buttons in various sizes ready made, with a stainless steel screw in the kit ready to go. My previous skiing use was to hold the bungy loop of a “rat tail” skin setup, as these buttons have a suitable groove for that.

Cool tip, Andrew! Am looking forward to hearing about why crampons are worthless – seriously :-)

It’s a complex theory that requires an illustration, so it might be a little while before I get around to explaining it.

In the meantime, there’s thread on it in the Forum:

http://www.straightchuter.com/forums/viewtopic.php?f=3&t=18

Howdy,

Andrew, thank you for the informative resource. I have just mounted TLT classics for use with F3’s and am going to use your “puck” method for the front shim, but I am a little unclear on the importance of the rear heel shim. Do you know if it is needed for the boot/binding combination to be safe.

Thanks

Hi Scott – As far as I know, it is really only the front puck that matters. I have never used a rear shim so I can’t comment on it.

I have cut a wine cork in half and gorilla glued it to the ski. Works great!

Brilliant tip! I’ve just mounted up a pair of TLT speeds which I’ll be using with the F3s. Only before I drill another hole in the skis for this lovely ghetto shim I was hoping to clarify the required thickness- 3/4″ seems to be way too thick, 6-8mm would work better I am thinking.

Is this due to a change in the height of the dynafit bindings since this was posted..? Or do I really need a shim which keeps my heel hovering 1″ above the ski?