Cheap Core-Shot Base Repair

After getting a cavernous core-shot repaired, I was so impressed with the quality of the repair I asked how much a good base-welder costs.

“About $1,200.”

Hmmm, I probably don’t need one that badly, but I do often rip moderate gouges in my bases that I’d like to repair, but aren’t worth the time and expense for a trip to the shop. I’ve also owned 2-3 cheap-o base repair guns and none of them seem to work, mainly because they don’t get hot enough. Base repair candles on the other-hand have some sort of additive (wax?) in them to keep them burning, but they don’t work well on deep gouges, especially if the drip gets soot in it, which is inevitable.

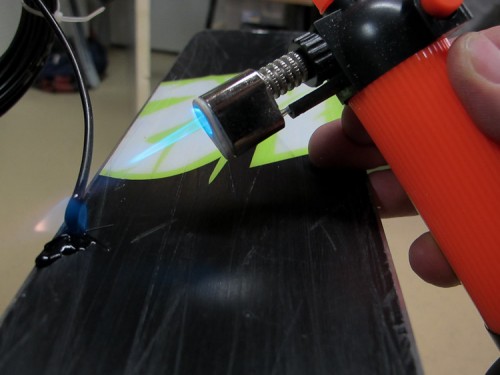

With this in mind, I’ve been having good success using a micro torch and spaghetti style “welding wire” base filler. The welding wire won’t stay lit by itself, but by using a clean burning micro torch, it liquifies and flows into deep gouges. With some finesse, you can also heat the base up a bit, which helps the welding wire patch adhere.

The welding wire comes from Sun Valley Ski Tools and the $7.00 micro torch comes from Harbor Freight. The torch runs on butane, which can be found at 7-11 type stores in the lighters & cigs section.

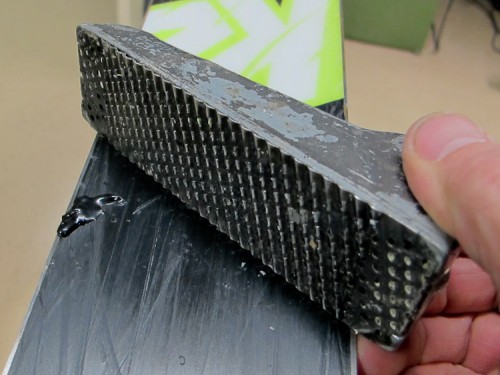

Once the gouge is filled to overflowing, use a Surform Pocket Plane to knock off the high spots and then scrape it flat with a sharp steel scraper.

There is not enough bandwidth on the internet to detail all that could go wrong with this scenario, including burning down your house, ruining your skis, or serious bodily harm, but with some practice, it does a passable job and deep repairs won’t pop out.

________________________________

Help support StraightChuter.com and wax over your repairs with a Toko T8 Wax Iron from Backcountry.com. Click on the photo below…

Category: 02 Gear, Gear Reviews

NIce! I will give that a go as well.

I use a big soldering iron (80watt, it gets plenty hot enough) that is about 10mm wide at the tip. That also works quite well, it also provides you with entirely novel array of ways to burn your house down..Just with a slower start

Been trying to stick with black bases on my splitboards, because my lighter ptex candle always soots everything up, and candle repair looks turdy on non-black base. Unfortunatly very hard to find black bases as of late. going to try this torch w clear.

love post like these and belay one! keep em comming!

For years I’ve used a mixture of 2-part urethane epoxy and powdered graphite, both available from Sun Valley Ski Tools. I go with the long-set epoxy because it seems to hold better, and my theory is the powdered graphite allows wax to penetrate the repair some. Could be complete bunk, though. But I’m convinced that the urethane epoxy allows for enough flex that it won’t pop out of the gouge. I’ve used it on many a core-shot and have never had one pop out.

Once the epoxy has set, you can use the above method for planing flat, but my preference is the panzar file instead of the surform plane. With a little control, you can get it smooth enough that the sharp steel scraper won’t have much work to do.

And the added benefit is the epoxy won’t get hot enough to burn your house down. You’ll just have to wait longer for it to set up.